Technology transfer: Best practices for optimizing success and mitigating risk in sterile drug manufacturing

Article

When planning a technology transfer for a parenteral product, partnering with a CDMO that has a proven track record is crucial for success. Our article “Technology transfer: Best practices for optimizing success and mitigating risk in sterile drug manufacturing”, explores the essentials of efficient and effective technology transfers. We highlight 12 key attributes of proficient technology transfer teams, including synchronized scheduling to meet project deadlines, consistent communication to align with customer expectations, and cross-functional expertise that fosters innovation and problem-solving.

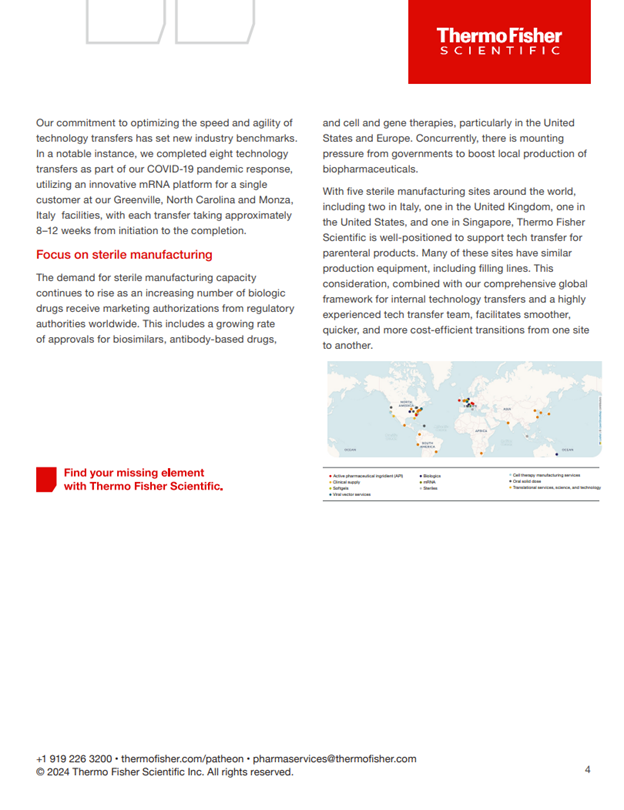

Collaborating with a CDMO that excels in these areas is vital for ensuring on-time, cost-effective technology transfers for your sterile drug manufacturing projects. By leveraging the key strategies and considerations discussed in this article, you can enhance the efficiency and effectiveness of your next technology transfer—ultimately helping get your innovative product to patients in need. Additionally, discover information about Thermo Fisher Scientific’s five sterile manufacturing sites around the world, all equipped to provide biotech and pharma companies with industry-leading technology transfer services.