cGMP cell therapy development and manufacturing services

Combining technical expertise with agile execution to address your unique project needs

While cell therapies offer an exciting new treatment paradigm for patients, there are many complex factors that may limit their commercial success, including analytics, scalability, regulatory hurdles, and more. At Thermo Fisher Scientific, we recognize the importance of an individualized approach to your development and manufacturing strategy to help navigate these challenges together. As a full-service cell therapy CDMO partner, we provide process and analytical development and cGMP manufacturing to support customers from clinical through commercial phases. For early-stage customers, our Translational Services team enables the accelerated and effective translation of cell therapy research through early establishment of standardized processes and qualifiable analytics which can be seamlessly transferred to our cGMP facility.

Experience in a variety of cell therapy types

We offer a foundation of support systems and technical expertise in a variety of modalities, including:

- Autologous and allogeneic cell therapies

- Viral and non-viral modified gene delivery systems

- T-cells, NK cells, iPSCs, MSCs, APCs, hESCs, blood and bone marrow-derived stem cells, and more

Flexibility and speed to market

As part of Patheon pharma services, we’ve been active in pharmaceutical manufacturing for more than 20 years and have the expertise and flexibility you need to continue moving at a rapid pace. Our approach to manufacturing readiness balances the need for speed with an unwavering focus on quality and innovation. Leverage our Rapid Development FrameworkTM consisting of established, optimized processes for various cell types and analytics with customizable components, enabling you to maintain control while leveraging standardized elements for efficiency and reliably. Alternatively, we can also collaborate with you to develop an entirely new solution for your unique therapeutic product. And when ready to transition to cGMP manufacturing, our individual, user-configurable suites at our state-of-the-art facility in San Francisco, CA can be customized to maximize efficiency of your process and ensure long-term scalability as you move toward commercialization.

A holistic approach to cell therapy CDMO services

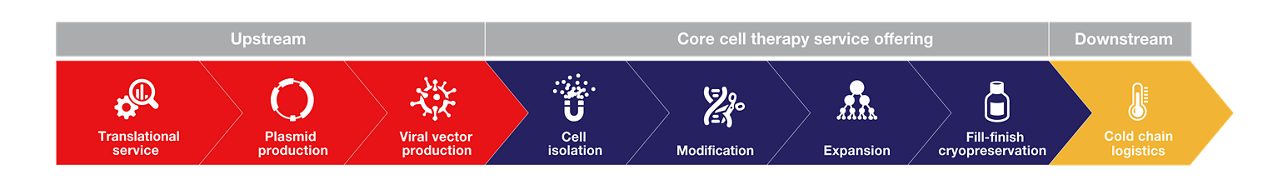

In addition to core cell therapy manufacturing services, we also provide upstream and downstream offerings to support all aspects of your development journey. From early translational research services to help optimize your process at a small scale, to cold chain logistics to facilitate secure storage and distribution of your final product, we’re a one-stop solution for managing your unique cell therapy project needs.

Our team employs a methodical approach to clinical and commercial readiness including process optimization, verification, and confirmation, ultimately saving time and reducing costs. Key elements of our cell therapy process development service are described below:

- Process optimization, scale-up, and capacity modeling

- Process and product characterization

- Assessment for opportunity to automate or close existing processes

- Cryopreservation formulation development and controlled rate freezing

- Product comparability and stability studies

- Cell isolation, washing, and volume reduction steps using closed systems

- Transfer of manufacturing workflow to cGMP suites

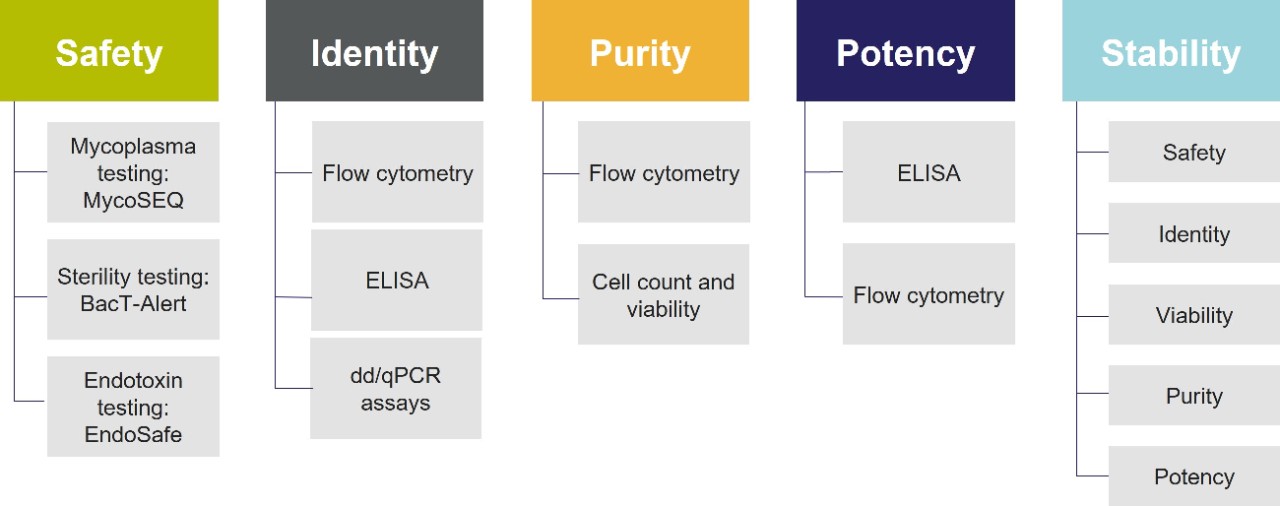

Analytical development is a critical aspect of the manufacturing process to ensure safety, identity, purity, potency and stability of cell therapy starting material, in-process material, or the final product. At Thermo Fisher Scientific, we follow a stringent workflow to develop robust and compliant methods that can be easily transferred to our quality control space.

- Service offering includes assay development, qualification and validation to accurately characterize your product

- Analytical testing available for starting material (safety), in-process material (monitoring and decision points), and final product (lot release testing)

- Comprehensive assay menu addresses safety, identity, purity, potency, and stability testing

- All assays compliant with industry standards and regulatory guidelines

- Customized assay development available upon request

- Assays performed in-house to facilitate time savings and reduce risk

The regulatory landscape for advanced therapies is constantly evolving, and what’s acceptable today may not be adequate tomorrow. For over 15 years we have supported customers with global regulatory interactions (US, EU, and Canada), CMC regulations, guidelines, and inspections. In addition to providing document reviews and gap analyses, our regulatory services team can generate documents to reduce the number of intermediaries and lead times in preparing regulatory filings.

- CMC dossier writing

- Gap analysis and CMC dossier review

- CMC regulatory strategic consulting

- Health authority meeting, filing, and inspection support

- Familiarity with shifting regulatory guidelines

Our 44,000 sq ft state-of-the-art facility is adjacent to numerous oncology hospitals in the Bay Area and ~15 minutes from the San Francisco International Airport. Equipped with individual, user-configurable cGMP-production suites, we can support multiple cell lines/multiple products simultaneously due to our unique dedicated HVAC system for each suite.

Helpful Resources