Viral vector development and manufacturing services

Unparalleled experience manufacturing viral vector products for more than 20 years

Viral vector production employs complex processes resulting in varying challenges throughout the product lifecycle. The main issues revolve around selecting a production system, optimizing product quality, and building standardization to enable a robust CMC approach.

Thermo Fisher Scientific viral vector services (VVS) is a leading CDMO that offers a full range of services for the development and commercialization of viral vectors and gene therapy-based vaccines. Our viral vector end-to-end capabilities include process and analytical development, clinical and commercial manufacturing, and fill-finish services. With an extensive network of production sites, global clinical supply chain capabilities, and in-depth viral vector technical and regulatory expertise, we can help you de-risk and expedite your therapy's path to market.

20+ years viral vector experience

Development and manufacturing

3 commercially approved products

and several others pending

1,100+ lots manufactured

1,100+ viral vector lots manufactured, including GMP clinical and commercial lots over time

35+ viral vector drug substance suites

and 6 viral vector drug product suites

The expertise and experience to design a path from early discovery to commercial manufacturing

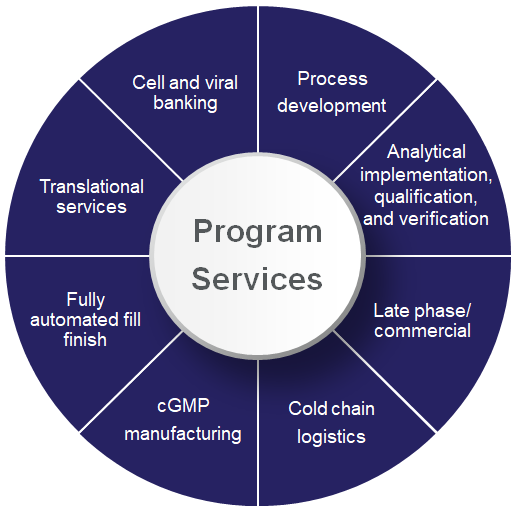

In addition to core viral vector manufacturing services, we also provide upstream and downstream offerings to support every aspect of your drug development and manufacturing journey. From early translational services to help optimize your small-scale processes to cold chain logistics to facilitate the secure storage and distribution of your final product, we provide end-to-end solutions for managing unique gene therapy and gene-modified cell therapy projects.

Viral vector types and platforms

While the viral vector market is dominated by adeno-associated viruses (AAV) and lentiviral vectors (LV), there is also a range of less commonly used vectors. Our suspension and adherent processes can be tailored to fit your product, indication, and delivery route based on our diverse expertise in viral vector production. Regardless of your vector strategy, you can be confident that we have the experience and resources to smoothly manage any project.

Specializing in adeno-associated virus (AAV) vectors across various serotypes, we excel in triple transfection and infection techniques for both adherent and suspension cell cultures. Our commitment to excellence ensures efficient and reliable AAV production, meeting the rigorous standards of pre-clinical, clinical, and commercial applications.

We bring extensive experience in process development and GMP production of lentiviral vectors (LV), utilizing both transient transfection and stable packaging cell line-based processes on adherent and suspension platforms. Our expertise has successfully led to the commercialization of products, including a CAR-T therapy, using these LV processes.

Other vector types

In addition to AAV and LV, we also have experience with the following viral vector types leveraging a variety of production platforms.

- Adenoviral

- Retrovial (RV)

- Herpesviral (HSV)

- Modified Vaccinia Ankara (MVA)

- Vesicular Stomatitis Virus (VSV)

- Virus-Like Particles (VLP)

Viral vector CDMO capabilities from discovery to commercialization

From process development and process characterization to manufacturing, QC, and fill-finish, VVS has the broad capabilities and expertise needed to develop and manufacture your viral vector product.

With over 20 years of experience creating viral vector products, we have established strategies for upstream and downstream process development and optimization, process scale up, and at scale pilot run standards. Throughout your product life cycle, you'll be guided through each milestone with checkpoints to ensure you meet all quality standards.

Suspension and adherent modalities |

Chromatography-based purification |

Customization and development |

Mammalian and insect cell culture |

Optimization for increased yield/recovery |

Platform assays |

Design of experiments |

Full capsid separation |

Process development testing support |

Scale up |

Specific purity requirements |

Pre-clinical material testing |

Our dedicated viral vector facilities manufacture CGMP-compliant viral vectors for clinical and commercial applications around the world. The 50 drug substance suites can be used for various production modes and technologies (cell factories, iCELLis, SUBs, etc.). Using semi and fully automated fill lines and a range of prequalified vial and container closure systems, we offer a comprehensive aseptic fill and finish service. Through our global technology transfer strategy, we facilitate the successful transfer and establishment of processes into our facilities from our customers or from internal development and pilot laboratories. Quality control (QC) capabilities are available at each site for in-process, release, and stability testing using approved or validated methods.

The regulatory landscape for advanced therapies is constantly evolving, and what is acceptable today may not be adequate tomorrow. Over 15 years, we have supported customers with global regulatory interactions (US, EU, and Canada), CMC regulations, guidelines, and inspections. In addition to providing document reviews and gap analyses, our regulatory services team can generate documents to reduce the number of intermediaries and filing lead times in preparing regulatory filings.

|

|

|

|

Learn how we can help you to navigate regulatory requirements for cell and gene therapies: download fact sheet.

The successful commercialization of your advanced therapy depends on rigorous technology transfer, robust process validation, and specialized regulatory support. Partnering with an organization capable of scaling alongside you ensures sustained capacity, while integrated services streamline your value chain, minimizing risk and accelerating market entry.

- 8 upcoming and ongoing PPQs across VVS sites

- 8 completed process characterizations

- 350+ commercial DS batches

- 250+ commercial DP Batches

- 3 approvals with major regulatory agencies (FDA, EMA, Japan)

- Manufactured in US and EU

Viral vector service offerings

To provide flexibility and agility for our customers, we offer several different pathways for viral vector development to support various manufacturing strategies, timelines, and customization needs.

Rapid Development Framework™ (open platform)

Accelerated development approach for AAV and LV leveraging pre-established processes and analytics with time to delivery of GMP drug product in as little as 9 months.

Customizable development

Flexible development and process solutions for a variety of viral vector types (AAV, LV, AdV, RV, HSV, MVA, VSV, and others) with time to delivery of GMP drug product in 12+ months.

Client tech transfer

Direct transfer and manufacturing of client process with time to delivery of GMP drug product in 9+ months.

Our viral vector manufacturing sites

A global footprint of over 555,000 square feet is available to develop and manufacture viral vector products. We can find suitable capacity, talent, and technology to ensure a robust product and efficient production processes at multiple sites. We are leveraging the viral vector knowledge and experience from Brammer Bio and Henogen S.A., as well as clinical trial capabilities from Fisher Clinical Services.

State-of-the-art Plainville site (290,000 ft2) designed for end-to-end viral vector services, from process development to commercial manufacturing, with unparalleled capacity and capabilities to meet market demands.

The Seneffe site (34,000 ft2) supports both clinical and commercial manufacturing. This site has over 20 years experience in virus and viral vector manufacturing and has been previously approved by EMA for commercial vaccine production.

Our Cambridge facility (140,000 square feet) performs process characterization, process validation, late-phase, and commercial manufacturing. This site has been manufacturing viral vectors since 2018 and received its first commercial license in Q1/2021.

The Gosselies site (8,300 ft2) specializes in process development, analytical development, early-phase clinical manufacturing, and process characterization for process validation.

Helpful Resources