Experience end-to-end cold chain supply solutions

Ensure your temperature-sensitive materials are safe with our reliable, end-to-end cold chain logistics services and support.

Discover a truly end-to-end supply chain solution

Thermo Fisher Scientific is helping to revolutionize the world of cold chain logistics with our truly end-to-end supply chain solutions. From cold to cryo, we can handle a wide array of biomaterials, with services spanning transportation, warehousing, labeling, packaging, and distribution. Learn more about our industry-leading capabilities here.

Critical biological material management

Download our fact sheet to discover how we deliver life-changing treatments to patients in need.

Clinical trial services that can be tailored to your unique trial needs

Our services span IMP, comparator, and ancillary clinical supplies, including strategy, sourcing, management, packaging and labeling, storage, and distribution

Aseptic fill finish at the volumes you need, and at the quality you demand

With flexible solutions to fit your unique timeline and budget

Tips for achieving technology transfer success

Technology transfers can be tricky. A misstep or delay in one area can snowball into problems in other areas of the project. Likewise, inadequate planning or poor execution can introduce major risks and put the end goal of the project in jeopardy. The necessary foresight and a detailed project plan are essential elements to ensure the project runs smoothly, both on-time and on-budget, to achieve the ultimate end goal of regulatory approval. Check out our infographic to learn the 9 key tips for making your tech transfer easy and painless.

Top tips for painless tech transfers

Discover our top tips for a smooth and successful tech transfer.

End-to-end advanced therapy development and manufacturing services

Over 20 years of cGMP manufacturing experience, expanding capacity, and global supply network

Cell and gene therapies in the US vs. the EU:

Top five areas of differentiation

For cell and gene therapies (CGTs) and other complex biologics, US and EU regulatory processes vary by more than just jurisdictional oversight. In this eBook we share the five key differences in the drug development and review process for companies hoping to gain market access through US Food and Drug Administration (FDA) or European Medicines Agency (EMA) approval—as well as tips for navigating these differences.

Cell and gene therapies in the US vs. the EUs

Explore the major differences in the drug development and review process for companies in the US vs. the EU.

Your missing element: A trusted global CDMO partner

Bringing a new medicine to market requires a carefully coordinated approach. From early-stage R&D to clinical supply and commercial manufacturing, you need a trusted partner to guide you every step of the way.

Enter Thermo Fisher Scientific’s Patheon pharma services.

As one of the industry’s most well-recognized contract development and manufacturing organizations (CDMOs), we help biotechnology and pharmaceutical sponsors accelerate their drug development journeys.

Our 360° CDMO and CRO solutions support your aspiration to get treatments to patients faster.

How we can partner with you

We are your strategic partner for integrated drug development. We share your goals of improving patients’ lives and making the world a healthier place. Dedicated to excellence through effective partnership, we take pride in our collective ability to help you at every step of the development lifecycle, working as one team for a seamless experience.

Explore our end-to-end solutions and capabilities, access our extensive resource library, and learn the benefits of having a partner with global expertise.

Innovative solutions

Get new medicines to patients faster. Our CDMO and clinical trial services simplify and accelerate your journey to market.

Learn how

Our capabilities

Remove barriers in the drug development process- from early development through communication and everything in between.

Explore our CDMO services

Insights and resources

Drug development is an ever changing industry. Stay connected to new discoveries, innovations, and expert scientific options.

Find helpful resources

Global site locations

With more than 60 locations worldwide, we are committed to providing integrated, end-to-end solutions across all phases of development.

See where we are

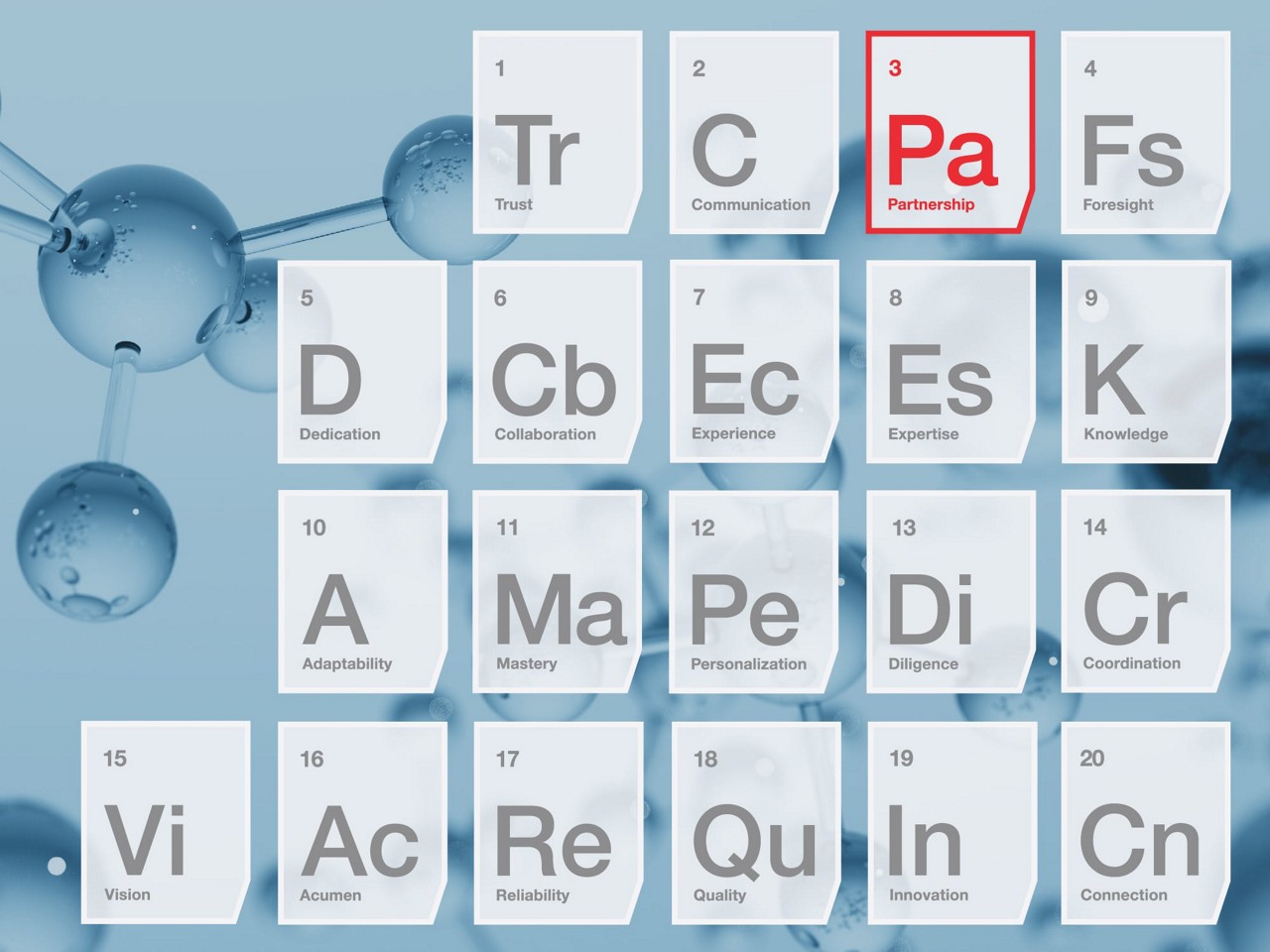

The elements of partnership coupled with scientific and operational excellence

Take advantage of our expertise in drug development with an unparalleled global network of sites; scientific, technical, and regulatory experts; a comprehensive range of tailored solutions; and flexible business models customized to meet your unique needs. Our integrated solutions include powerful digital platforms for timely visibility and collaboration, streamlined project management and partner communication, and our commitment to full project and process transparency at every step of your drug development journey.

The elements of partnership coupled with scientific and operational excellence

Take advantage of our expertise in drug development with an unparalleled global network of sites; scientific, technical, and regulatory experts; a comprehensive range of tailored solutions; and flexible business models customized to meet your unique needs. Our integrated solutions include powerful digital platforms for timely visibility and collaboration, streamlined project management and partner communication, and our commitment to full project and process transparency at every step of your drug development journey.

Latest features and insights

Ready to discuss your project?

Find your missing element with Thermo Fisher Scientific